Services

- SLA,SLS,FDM,3D PRINTING Click Here

-

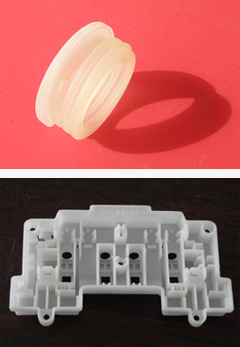

SLA – Stereolithography. Material: Epoxy Resin

SLA – Stereolithography. Material: Epoxy Resin

SLS – Selective Laser Sintering.

Material: Nylon,ABS,PP,PVC,Aluminum

The prototype can be sanded, glued, and painted, silk-screeen,and surface texture very similar to that of production materials.

Methodology of Rapid Prototyping

The basic methodology for all current rapid prototyping techniques can be follows:

1. A CAD model is constructed, then converted to STL format.The resolution can be set to minimize stair stepping.

2. The RP machine processes the .STL file by creating sliced layers of the Model.

3. The first layer of the physical models is created. The model is then lowered by the thickness of the next layer,and the process is repeated until completion of Model.

4. The model and any supports are removed .The surface of the model is then finished and cleaned.

3D Printing Technology is a new technology, which offers customers an accurate and fast process in obtaining coloured prototype

3D Printing is suitable for evaluating the physical form, aesthetics and function of a design.

- CNC Prototypes Manufacturing Click Here

- Rapid Silicone Mould & Vacuum Casting Click Here

- Rapid Tooling Click Here

- Injection Molding Click Here

- Why rapid prototyping? Click Here

CNC machinging parts is the process by which material is removed from a workpiece with Computer Numerical Control (CNC) equipment that cuts away unwanted material .Machining is possible in real materials,Parts are machined directly from your 3D CAD models.

CNC machinging parts is the process by which material is removed from a workpiece with Computer Numerical Control (CNC) equipment that cuts away unwanted material .Machining is possible in real materials,Parts are machined directly from your 3D CAD models. Rapid tooling and Vacuum duplication

Rapid tooling and Vacuum duplication Explorer offers fully machined steel tools or aluminium tools for low to medium volume parts within 15-45 days (depending on complexity).

Explorer offers fully machined steel tools or aluminium tools for low to medium volume parts within 15-45 days (depending on complexity). We are capable of producing high qulity tooling and injection that meets Eruopean and Amercian mould standards.

We are capable of producing high qulity tooling and injection that meets Eruopean and Amercian mould standards. Prototypes allow the design team to test for functionality and ensure design and fit is correct.

Prototypes allow the design team to test for functionality and ensure design and fit is correct.